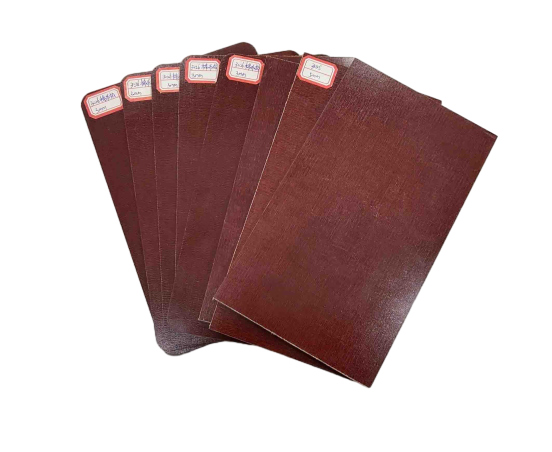

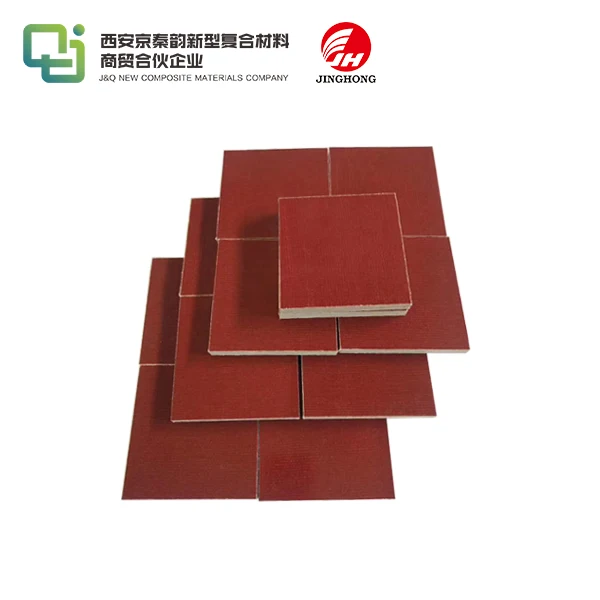

Phenolic Resin Board

Basic Information:

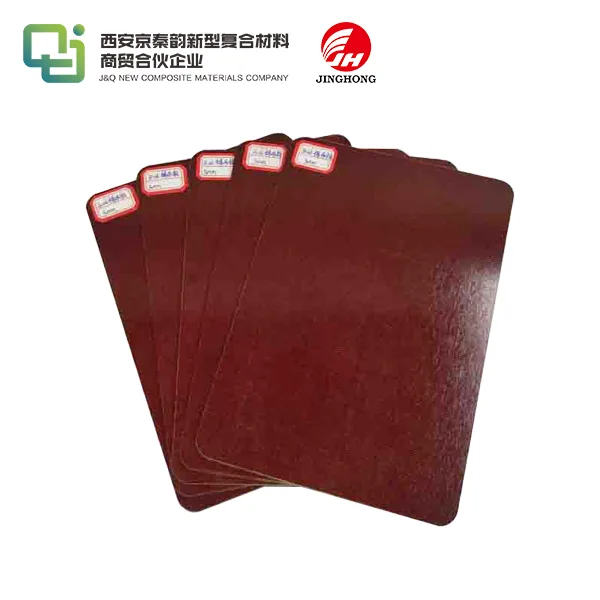

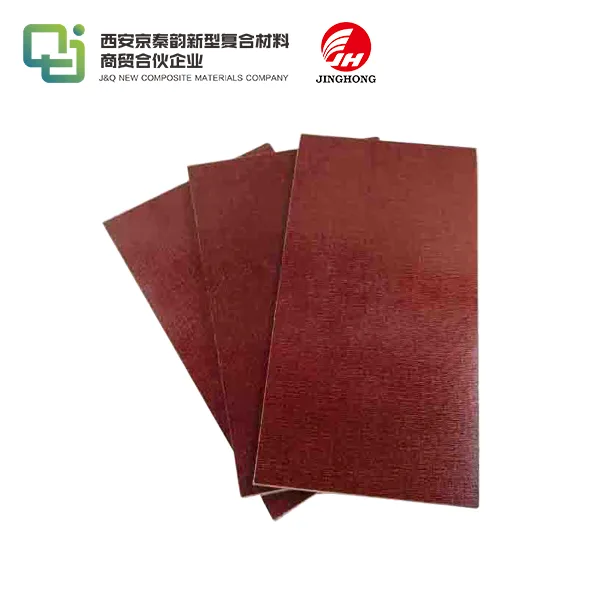

Brand: JingHong

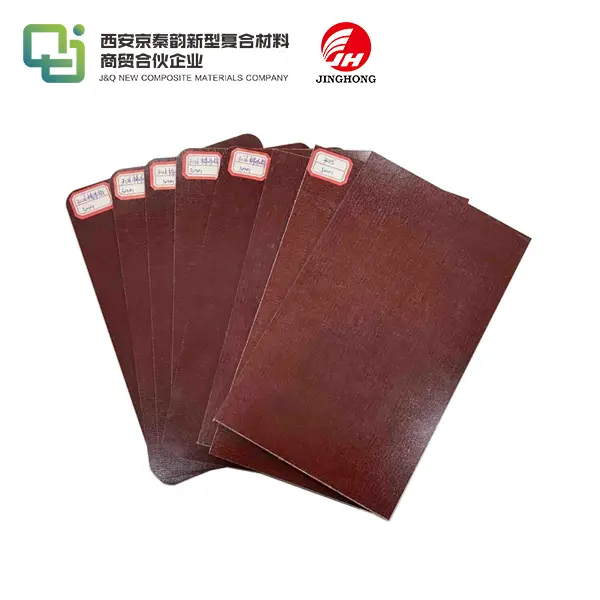

Grade: 3025,3026

Color: Brown,Black

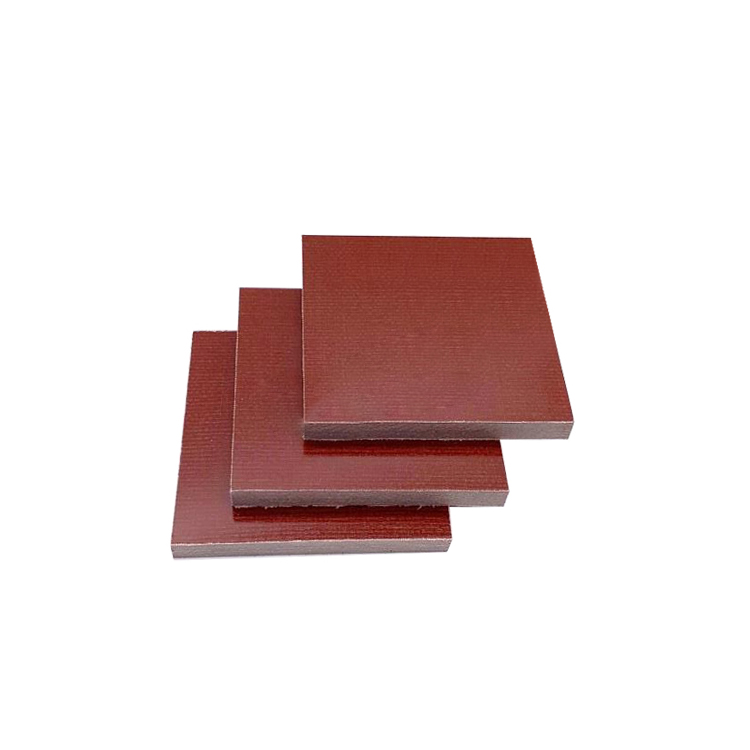

Thickness: 2mm --- 100mm

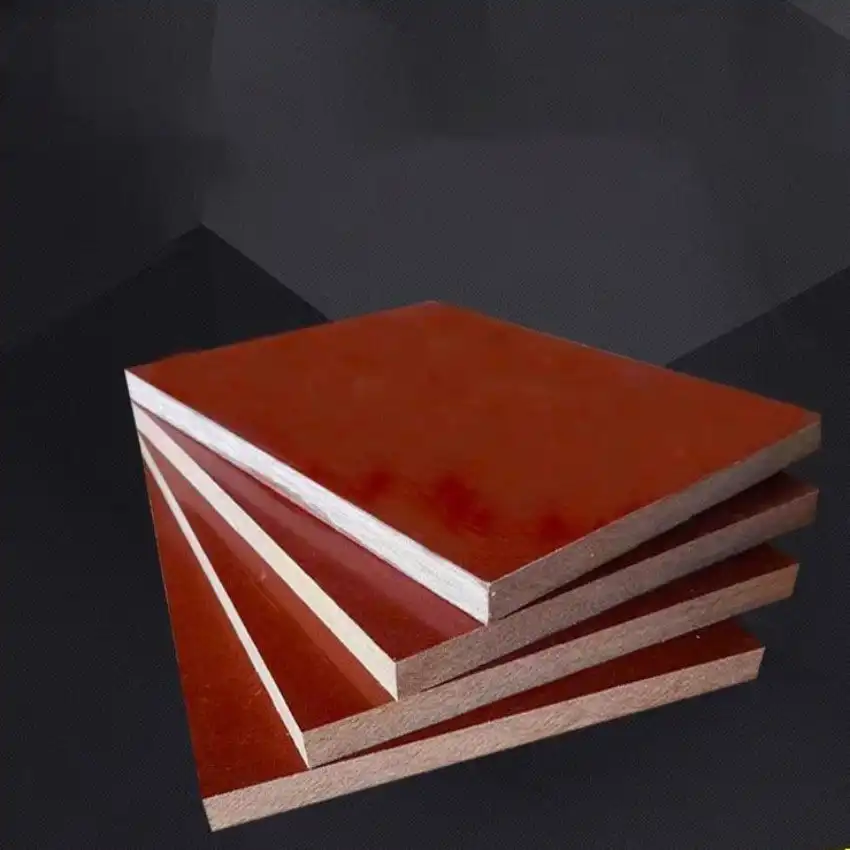

Material: Cotton Fabric + Phenolic Resin

Regular Size:1020mm*2020mm,1220mm*2440mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Premium Phenolic Resin Board - High-Performance Industrial Insulation Material

When you require dependable electrical separator with uncommon mechanical quality, our Phenolic Resin Board conveys exceptional execution for requesting mechanical applications. Made by J&Q Unused Composite Fabric Bunch Co., Ltd beneath the trusted JingHong brand, this premium composite fabric combines cotton texture support with phenolic gum to make a flexible arrangement for electrical and mechanical components. Our product meets exacting quality guidelines whereas advertising great solidness and temperature resistance.

Product Description from the Supplier

Our JingHong brand composite sheets include high-quality cotton texture fortification impregnated with phenolic gum. Accessible in grades 3025 and 3026, these sheets come in classic brown and dark colors to suit your tasteful necessities. Standard thickness alternatives run from 2mm to 100mm, pleasing different application needs. Normal sizes incorporate 1020mm×2020mm and 1220mm×2440mm, with custom measurements accessible upon request.

Product Availability

| Attribute | Details |

|---|---|

| Current Stock Status | Ready for immediate shipment |

| Production Capacity | 30,000 tons annually |

| Minimum Order Quantity | 500KG |

| Lead Time | Contact us for specific delivery schedules |

| Shipping Options | Ocean, land, and air transportation available worldwide |

Key Features

- Superior Electrical Properties: Fabulous breakdown voltage execution in transformer oil testing

- Temperature Flexible: Lesson E rating withstands nonstop operation up to 120°C

- Mechanical Brilliance: Exceptional wear resistance and basic integrity

- Versatile Thickness Extend: 2mm to 100mm alternatives for different applications

- Premium Materials: High-grade cotton texture with phenolic tar matrix

- Standard Sizes: Different measurements accessible for quick use

Standards

Our fabricating forms comply with universal electrical separator measures. Each Phenolic Resin Board experiences thorough quality testing to guarantee steady execution. Testing methods incorporate breakdown voltage estimations in transformer oil at controlled temperatures of 90±2°C. temperatures of 90±2°C.

Technical Features: Product Safety Control

| Category | Attribute | Details |

|---|---|---|

| Electrical Performance | Parallel-layer breakdown voltage | ≥10kV (tested in transformer oil at 90±2°C) |

| Perpendicular layer electrical strength | 1.0mm thickness: ≥0.82 kV/mm 3.0mm thickness: ≥0.50 kV/mm | |

| Thermal Properties | Temperature Rating | Class E (120°C continuous operation) |

| Heat Resistance | Maintains structural integrity under thermal stress | |

| Mechanical Characteristics | Wear Resistance | Exceptional durability for moving components |

| Dimensional Stability | Minimal thermal expansion and contraction | |

| Impact Resistance | Superior shock absorption capabilities |

Product Application

Our products serves different mechanical divisions effectively:

Electrical Industry:

- Transformer cover components

- Switchgear assemblies

- Circuit breaker parts

- Motor opening wedges

Mechanical Applications:

- Planetary adapt systems

- Wear plates and bushings

- Insulated basic components

- Bearing retainers

Industrial Equipment:

- High-temperature gaskets

- Electrical board backing

- Machinery wear strips

- Insulation barriers

|

|

|

OEM Service

We give comprehensive OEM arrangements custom fitted to your determinations. Our building group works closely with you to create custom measurements, grades, and execution characteristics. Whether you require specialized thickness necessities or special measure arrangements, our adaptable fabricating capabilities oblige your correct needs.

Custom Administrations Include:

- Precision cutting and machining

- Special thickness requirements

- Custom bundling solutions

- Technical back and consultation

FAQ

Q: What makes phenolic tar sheets appropriate for high-temperature applications?

A: The phenolic tar lattice gives great warm solidness with Lesson E temperature rating, permitting nonstop operation at 120°C whereas keeping up electrical and mechanical properties.

Q: How do you guarantee steady quality over generation batches?

A: We execute comprehensive quality control testing counting electrical breakdown voltage estimations and mechanical property confirmation for each generation batch.

Q: Can you give custom sizes past the standard dimensions?

A: Yes, our fabricating capabilities incorporate custom cutting and measuring to meet your particular application necessities. Contact us with your dimensional needs.

Q: What is the commonplace life expectancy of phenolic gum sheets in electrical applications?

A: With legitimate establishment and inside evaluated working conditions, these sheets give decades of solid benefit in electrical separator applications.

Contact Us

Ready to enhance your projects with premium composite materials? Our technical specialists are available to discuss your specific requirements and provide detailed Phenolic Resin Board recommendations.

Get in touch today:

- Email: info@jhd-material.com

- Expert Consultation: Available for technical specifications and application guidance

- Sample Requests: Contact us for material samples and testing

Trust J&Q Modern Composite Fabric Bunch Co., Ltd for your mechanical cover needs. We combine decades of fabricating skill with cutting-edge quality control to convey materials that surpass your desires.

Send Inquiry