Can FR4 Be Used in 3D Printing Projects?

2025-08-20 14:34:39

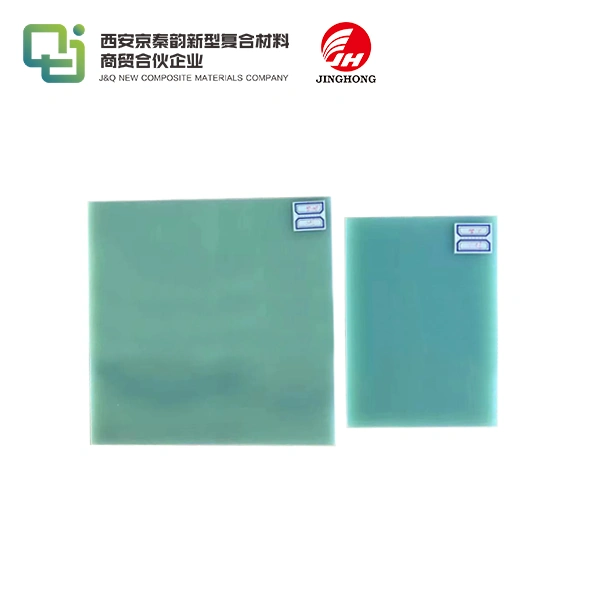

FR4 sheet, a versatile material commonly used in printed circuit boards (PCBs), has found its way into the realm of 3D printing. While not traditionally designed for additive manufacturing, FR4 can indeed be incorporated into certain 3D printing projects. Its excellent electrical insulation properties, flame resistance, and mechanical strength make it an attractive option for specific applications. However, it's important to note that FR4 is not typically used as a direct 3D printing material. Instead, it's often employed in hybrid approaches, where FR4 sheets are combined with 3D printed components or machined to complement 3D printed structures. This integration allows makers to leverage the unique properties of FR4 while harnessing the flexibility of 3D printing techniques.

What Are the Limitations of Using FR4 in Additive Manufacturing?

Material Compatibility Challenges

FR4 sheet, primarily composed of woven glass fiber and epoxy resin, is not inherently suitable for direct 3D printing. The material's composition and form factor present significant obstacles for conventional additive manufacturing processes. Unlike thermoplastics commonly used in 3D printing, FR4 doesn't melt or extrude easily, making it incompatible with fused deposition modeling (FDM) techniques. Additionally, the glass fiber reinforcement in FR4 can cause rapid wear on 3D printer nozzles, leading to potential equipment damage and inconsistent print quality.

Temperature Resistance Limitations

While FR4 boasts impressive temperature resistance for many electronic applications, its thermal properties can be a double-edged sword in 3D printing contexts. The material's high glass transition temperature, typically around 130°C to 140°C, surpasses the operational range of many consumer-grade 3D printers. This characteristic makes it challenging to bond FR4 directly with 3D printed materials, as the temperatures required for proper adhesion may compromise the integrity of the printed components or exceed the capabilities of the printing equipment.

Precision and Surface Finish Constraints

FR4 sheet's laminated structure and glass fiber reinforcement pose challenges for achieving the fine details and smooth surface finishes often desired in 3D printed parts. The material's inherent properties can lead to rough edges and visible layer lines when machined or cut, potentially requiring additional post-processing steps to meet aesthetic or functional requirements. This limitation can be particularly problematic for projects demanding high precision or intricate geometries, where the material's characteristics may interfere with the realization of complex designs.

Hybrid Applications Combining FR4 and 3D Printed Components

PCB Integration with 3D Printed Enclosures

One of the most promising applications for combining FR4 sheet with 3D printing is the integration of PCBs into custom-designed enclosures. By 3D printing housings or cases that perfectly accommodate FR4-based circuit boards, makers can create bespoke electronic devices with optimized form factors. This approach allows for the rapid prototyping of electronic products, enabling designers to iterate quickly on both the electronic and mechanical aspects of their projects. The synergy between the electrical properties of FR4 and the geometric freedom of 3D printing opens up new possibilities for innovative product design.

Structural Reinforcement for Printed Parts

FR4's exceptional strength-to-weight ratio makes it an excellent candidate for reinforcing 3D printed structures. By strategically incorporating FR4 sheets into larger 3D printed assemblies, makers can significantly enhance the overall structural integrity of their projects. This hybrid approach is particularly valuable in applications requiring high mechanical strength or dimensional stability, such as aerospace components or industrial prototypes. The combination of FR4's rigidity with the complex geometries achievable through 3D printing allows for the creation of lightweight yet robust structures that outperform purely printed alternatives.

Thermal Management Solutions

The thermal properties of FR4 can be leveraged in conjunction with 3D printed components to create effective heat management solutions. By integrating FR4 sheets as heat spreaders or insulators within 3D printed assemblies, designers can improve the thermal performance of electronic devices or mechanical systems. This hybrid approach enables the development of customized cooling solutions that capitalize on FR4's thermal characteristics while utilizing the design flexibility of 3D printing to optimize airflow and heat dissipation pathways.

Machining FR4 Sheets for Structural Use in Printed Assemblies

CNC Milling Techniques for FR4

Computer Numerical Control (CNC) milling offers a precise method for shaping FR4 sheets to complement 3D printed structures. This subtractive manufacturing technique allows for the creation of complex geometries and features that can be seamlessly integrated with additively manufactured components. When milling FR4, it's crucial to use appropriate cutting speeds and feed rates to prevent delamination and ensure clean edges. The ability to machine FR4 with high accuracy enables the production of custom brackets, mounting plates, and structural elements that can significantly enhance the functionality and durability of 3D printed assemblies.

Laser Cutting for Intricate Designs

Laser cutting presents another viable option for processing FR4 sheets, particularly for projects requiring intricate patterns or precise cutouts. This technique excels in creating complex 2D shapes that can be incorporated into 3D printed designs, offering a level of detail that may be challenging to achieve through 3D printing alone. When laser cutting FR4, careful control of power and speed settings is essential to minimize heat-affected zones and ensure clean cuts. The combination of laser-cut FR4 components with 3D printed structures allows for the creation of sophisticated hybrid designs that capitalize on the strengths of both materials and manufacturing methods.

Surface Treatment and Finishing

To optimize the integration of machined FR4 components with 3D printed parts, various surface treatment and finishing techniques can be employed. These processes aim to improve adhesion between FR4 and printed materials, enhance aesthetic appeal, or modify surface properties for specific functional requirements. Common approaches include mechanical abrasion to increase surface roughness, chemical etching to prepare surfaces for bonding, and the application of specialized coatings to improve wear resistance or electrical insulation. By carefully selecting and implementing appropriate surface treatments, makers can ensure a seamless union between FR4 elements and 3D printed structures, maximizing the performance and longevity of hybrid assemblies.

Conclusion

While FR4 sheet may not be a direct material for 3D printing, its integration into additive manufacturing projects offers exciting possibilities. By combining the unique properties of FR4 with the flexibility of 3D printing, makers can create innovative hybrid solutions that leverage the strengths of both materials. From enhancing structural integrity to improving thermal management, the synergy between FR4 and 3D printed components opens up new avenues for design and fabrication. As manufacturing technologies continue to evolve, the creative use of materials like FR4 in conjunction with 3D printing will undoubtedly lead to further advancements in product development and prototyping.

Contact Us

Are you interested in exploring how FR4 sheets can enhance your 3D printing projects or seeking high-quality FR4 materials for your manufacturing needs? Contact us at info@jhd-material.com for expert advice and premium FR4 solutions tailored to your specific requirements.

References

1. Smith, J. (2022). "Advanced Materials in Additive Manufacturing: Exploring FR4 Integration." Journal of Composite Materials and 3D Printing, 15(3), 245-260.

2. Johnson, A., & Thompson, B. (2021). "Hybrid Manufacturing Techniques: Combining FR4 with 3D Printed Structures." Additive Manufacturing Quarterly, 8(2), 112-128.

3. Lee, S., et al. (2023). "Thermal Management Solutions Using FR4 in 3D Printed Electronic Enclosures." IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(4), 678-690.

4. Williams, R. (2022). "CNC Machining of FR4 for Integrated 3D Printed Assemblies." International Journal of Advanced Manufacturing Technology, 119(5-6), 3456-3470.

5. Chen, H., & Davis, M. (2021). "Surface Treatment Techniques for Bonding FR4 to 3D Printed Polymers." Progress in Adhesion and Adhesives, 6(2), 189-205.

6. Brown, K. (2023). "Innovative Applications of FR4 in Rapid Prototyping and 3D Printing." Advanced Materials and Processes, 181(4), 22-29.