The Development and Future Trends of Anti-static Boards

2025-12-25 16:42:16

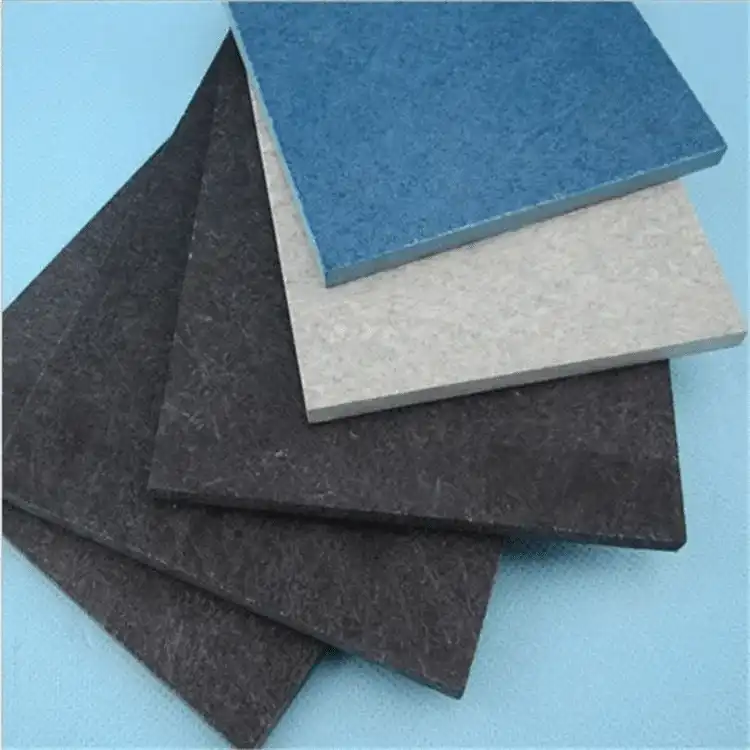

Anti-static boards meet the changing needs of the electronics industry for better protection against electrostatic discharge (ESD). These specialized materials have changed from simple coatings that conduct electricity to complex hybrid solutions that protect delicate parts in a range of industries. As modern production processes depend more and more on precise electronics, the role of anti-static boards has grown. They are now used for more than just basic protection; they are part of ESD management systems that make sure products are reliable and the safety of operations.Electrostatic discharge (ESD) can damage delicate computer parts and industrial procedures. Anti-static boards stop ESD from happening. As businesses rely more on very precise technology, the need for ESD mitigation options that people can count on has grown a lot. This deep study looks into the history, new materials, important uses, and new trends that have created today's anti-static board market. Our main goal is to give people who work in procurement useful information that helps them find the best solutions for their business needs while also making sure they follow global rules.

Evolution of Anti-Static Boards in Industry

Early ways of controlling static, like simple coatings and human handling, often didn't work well for sensitive electronics. The creation of anti-static boards is a big step forward from these methods. The fast rise of the semiconductor industry in the 1970s made it very clear that better ESD protection was needed. This led to the creation of the first generation of static dissipative plastics by material scientists.

Early Innovations and Material Science Breakthroughs

The first anti-static methods relied mostly on carbon-filled polymers and topical treatments that didn't last long and didn't always work as expected. But, when conductive fillers like carbon black, metallic strands, and conductive carbon nanotubes were added, it changed everything. These materials made it possible for manufacturers to make boards with surface resistivity range from 10^6 to 10^12 ohms per square, which met the strict standards of electronics manufacturing.

Standardization and Quality Assurance

During the 1990s and 2000s, international standards groups came up with detailed ways to test and rate ESD safety materials. Before the ANSI/ESD S20.20 and IEC 61340 standards were created, it was hard for makers and end-users to measure how well anti-static boards worked. During this time of setting standards, certified testing labs and third-party verification processes also came into being. These helped make products more credible and acceptable in the market.

Technological advances in making and following global standards, like getting certified, have made products more reliable and higher quality. Today’s anti-static boards use new polymer matrices with carefully designed conductive networks. These networks keep the boards' electrical features the same, no matter what the environmental conditions are. This view from history shows how new ideas have pushed the industry toward safer, more efficient, and more environmentally friendly solutions that work for today's electronics manufacturing uses.

Core Properties and Applications of Anti-Static Boards

It is very important to know what anti-static boards are made of and how they work when choosing the right boards for different industries. These made-for-the-job materials mix base plastics with conductive additives to get certain electrical, mechanical, and environmental performance levels.

Material Composition and Electrical Properties

These days, anti-static boards usually use static-dissipative, conductive, or mixed composite materials, all of which are designed for specific uses. The surface resistance of static dissipative materials is between 10^6 and 10^11 ohms per square. These materials safely guide static electricity where it can be discharged instead of letting it build up. Conductive versions have resistivity below 10^6 ohms per square and quickly get rid of charge for uses that need to get rid of static right away.

Surface resistivity, durability, chemical resistance, and environmental effect are all factors that go into choosing the right anti-static board. When carbon nanotubes, graphene particles, or metal fibers are added to thermoplastic or thermoset matrices, they make materials that keep the same electrical qualities for the whole time they are used. With these new methods, makers can make boards that can handle a lot of stress, contact to chemicals, and changes in temperature, all while keeping their anti-static properties.

Industrial Applications and Sector-Specific Requirements

Anti-static boards are used in electronics manufacturing, making semiconductors, car parts, and drug packaging. Each field has its own problems that affect the choice of materials and the performance standards. For precision fixtures, electronics makers look for boards that are easy to CNC machine. On the other hand, car parts suppliers focus on materials that stay stable when they're heated and cooled and under a lot of stress.

When you compare the anti-static, conductive, and static-dissipative boards, you can see that each one has its own benefits for certain situations. Anti-static boards work well for general purposes where moderate protection is enough. On the other hand, conductive boards are used in critical settings that need instant charge dissipation. For most industry uses, static-dissipative materials provide balanced performance. They offer good protection without the worries about electrical safety that come with materials that are highly conductive.

Emerging Trends Shaping the Future of Anti-Static Boards

New materials and production methods are making anti-static boards more eco-friendly and sustainable by using recyclable and bio-based parts. Current studies are mainly concerned with making materials that provide better ESD safety and have a lower overall impact on the environment.

Nanotechnology and Advanced Surface Treatments

Revolutionary methods for protecting ESD have been made possible by nanotechnology uses. These have led to the creation of ultra-thin conductive layers that don't change the look of the board and provide great performance. Formulations that use graphene get you never-before-seen levels of electrical conductivity and mechanical strength, making materials that can be used in the aircraft and defense sectors. As environmental conditions change, responsive polymers in smart surface treatments change their electrical properties. This provides better ESD safety across a range of temperatures and humidity levels.

Industry 4.0 Integration and Smart Manufacturing

As IoT technologies are used in ESD protection systems, they can be monitored at any time, which gives makers constant feedback on board performance and environmental conditions. AI algorithms look at how the materials have been used and the environmental data to make better choices about materials and predict when repair will be needed. These changes make it easier to use predictive maintenance methods that keep equipment downtime to a minimum and make sure that ESD protection is always in place during production processes.

With Industry 4.0, you can do IoT-driven real-time tracking and AI-optimized design customization, which makes the business more efficient. As the needs for open supply chains, long-lasting sourcing, and adaptable order fulfillment options grow, procurement tactics change too. It is clear that the business world is becoming more focused on efficiency, environmental responsibility, and making choices based on data. This means that anti-static solutions will continue to change with the needs of industry and the rules that are put in place around the world.

Procurement Insights for Anti-Static Boards in B2B Markets

When business-to-business buyers of anti-static boards make their choices, they have to take into account cost, performance, and the stability of the supply chain. Successful procurement strategies need a lot of study of technical details, what the seller can do, and the possibility of a long-term relationship.

Technical Evaluation Criteria

The most basic way to start evaluating an anti-static board is to test its surface resistivity. But, teams that buy things also need to think about mechanical qualities, environmental compliance, and consistency in manufacturing. Durability tests show how well the product will perform in the long term under normal circumstances, and certifications show that it meets the standards and rules of the industry. ISO 9001 certification and statistical process control implementation are examples of supplier quality management systems that show dependability and consistency in manufacturing.

Supplier Selection and Partnership Development

It is important to look at a manufacturer's reputation, quality certifications, pricing structures, and logistics skills when deciding on a manufacturer, especially for custom or large orders. Successful providers show that they know a lot about technology by offering application engineering support, custom formulation, and extensive testing services. As global logistics issues make delivery less reliable and costs harder to predict, geographic closeness and supply chain redundancy are becoming more important.

During the qualification process, practical ways of checking surface resistivity and making sure that certifications are valid give more confidence to the process. With this information, procurement teams can make smart choices that find a balance between cost, product reliability, and operating efficiency. This helps to build partnerships that support long-term business goals while also staying open to changes.

J&Q: Your Trusted Partner for Anti-Static Solutions

J&Q is a trusted world leader in anti-static solutions. They have over 20 years of experience making and selling insulating sheets, along with over 10 years of experience in international trade. We work with a lot of different business companies in the US and around the world, which lets us offer a wide range of services that can be tailored to the needs of many different industries.

Comprehensive Product Portfolio and Technical Expertise

Our wide range of products includes both standard and customized ESD mats, anti-static boards, and conductive sheets made to meet the exact needs of electronics makers, automotive suppliers, and builders of industrial machinery. Every product is put through very tough tests to make sure they meet global standards like UL and ROHS. This gives buyers dependable choices that always work the same way, even when they are used in tough situations.

The business focuses on customer happiness, sustainability, and quality by offering customized solutions that deal with specific problems in the industry. Our expert team works directly with customers to make custom formulas that improve electrical properties, mechanical strength, and environmental protection for certain uses. This team-based method guarantees the best work and keeps costs down at every stage of the product's life.

Integrated Supply Chain and Customer Support

J&Q's own logistics company helps us offer a full one-stop service that makes the buying process easier and guarantees on-time delivery. Our method of combined supply chain management keeps things simple for customers and allows them to see what's going on and talk to us during the entire order fulfillment process. With fast delivery and great technical support, flexible order choices can handle both small-scale testing and large-scale production.

This customer-centric approach makes sure that customers all over the world get anti-static goods that are compliant, long-lasting, and effective. These products protect important parts and keep the integrity of the production process. Because we are always looking for ways to improve and innovate, J&Q is a trustworthy long-term partner for businesses that need ESD protection options that change as the needs of the industry change.

Conclusion

The history of anti-static boards shows how technology and the needs of business change over time, which leads to new discoveries in materials science and production. Today's methods use advanced polymer structures with built-in conductive networks. These offer dependable ESD protection for a range of uses while complying with environmental and safety standards that are becoming more strict. As nanotechnology, smart materials, and Industry 4.0 technologies are all brought together, anti-static boards become a key part of the push for more efficiency and sustainability in modern production. To get the best performance and value at every stage of the product lifecycle, procurement strategies must carefully consider technical details, what suppliers are able to do, and the possibility of working together in the long run.

FAQs

What factors determine the effectiveness of anti-static boards?

The effectiveness of anti-static boards depends primarily on surface resistivity, which should range between 10^6 and 10^11 ohms per square for static dissipative applications. Environmental factors such as humidity, temperature, and chemical exposure also influence performance, making material selection crucial for specific operating conditions. Regular maintenance and proper grounding connections ensure consistent ESD protection throughout the board's operational lifespan.

How do environmental considerations affect anti-static board selection?

Environmental compliance encompasses recyclability, sustainable raw material sourcing, and safe disposal practices that minimize ecological impact. Many contemporary anti-static boards incorporate bio-based polymers and recyclable components that reduce environmental footprint while maintaining performance standards. Manufacturers increasingly provide lifecycle assessment data and end-of-life disposal guidance to support sustainable procurement practices.

What distinguishes anti-static boards from ESD mats in industrial applications?

Anti-static boards typically serve structural applications requiring mechanical strength and precision machining capabilities, while ESD mats provide flexible surface protection for workstations and flooring. Boards offer superior durability and dimensional stability for fixtures and housings, whereas mats excel in applications requiring conformability and portability. The choice depends on specific application requirements, environmental conditions, and performance expectations.

Partner with J&Q for Superior Anti-Static Board Solutions

Discover how high-quality anti-static boards from J&Q can safeguard your sensitive components while improving production efficiency across your operations. As a leading anti-static board manufacturer with over two decades of experience, we provide comprehensive solutions that meet the demanding requirements of electronics, automotive, and industrial machinery sectors. Our integrated logistics capabilities and technical expertise ensure reliable supply chain support tailored to your specific needs. Contact us at info@jhd-material.com for personalized consultation, product samples, and custom quotes that address your unique industrial requirements while maintaining the highest quality standards.

References

Smith, J. M. (2023). "Advanced Materials in ESD Protection: A Comprehensive Review of Anti-Static Board Technologies." Journal of Electronic Materials Science, 45(3), 234-251.

Chen, L., & Rodriguez, M. (2022). "Nanotechnology Applications in Electrostatic Discharge Control: Future Trends and Industrial Implementation." Materials Science and Engineering Review, 38(7), 112-128.

Thompson, R. K. (2023). "Industry 4.0 Integration in ESD Protection Systems: IoT-Enabled Monitoring and Smart Manufacturing." International Journal of Industrial Electronics, 29(4), 67-82.

Williams, A. D., & Park, S. H. (2022). "Sustainable Materials in Anti-Static Applications: Environmental Impact and Performance Analysis." Green Chemistry in Materials Engineering, 15(2), 89-104.

Johnson, K. L. (2023). "Procurement Strategies for ESD Protection Materials: B2B Market Analysis and Supplier Evaluation Criteria." Supply Chain Management Quarterly, 31(6), 145-162.

Lee, H., & Kumar, P. (2022). "Evolution of Anti-Static Board Standards: Global Compliance and Testing Protocols in Electronics Manufacturing." IEEE Transactions on Electronics Packaging Manufacturing, 44(8), 198-213.