FR4 Glass Epoxy Sheet: The Backbone of Modern Electronics

2025-07-23 17:18:10

Why is the FR4 glass epoxy sheet often hailed as the backbone of modern electronics? This remarkable material, a composite of woven fiberglass cloth and flame-retardant epoxy resin, delivers unparalleled strength, durability, and electrical insulation. Its versatility makes it indispensable in the production of printed circuit boards (PCBs), which power everything from smartphones to aerospace systems. With exceptional thermal resistance and mechanical stability, FR4 glass epoxy sheets ensure reliable performance in demanding environments. Manufacturers across the globe rely on this material to create cutting-edge electronic devices, cementing its role as a cornerstone of innovation in the electronics industry.

Unveiling the Power of FR4 Glass Epoxy Sheets

The Composition That Drives Excellence

What makes FR4 glass epoxy sheets so formidable in the world of electronics? The secret lies in their unique composition. These sheets are crafted from a blend of woven fiberglass cloth, which provides robust mechanical strength, and an epoxy resin binder that is flame-retardant. This synergy creates a material that is not only sturdy but also resistant to heat and chemical degradation. The "FR" in FR4 stands for "flame retardant," a critical feature that ensures safety in high-stakes applications. This composition allows the material to withstand the rigors of modern manufacturing processes, making it a preferred choice for insulating sheets in electronic assemblies.

Applications Across Industries

The reach of FR4 glass epoxy sheets extends far beyond a single niche. In the realm of consumer electronics, they form the foundation of PCBs in devices like laptops, televisions, and gaming consoles, ensuring seamless electrical performance. In the automotive sector, these sheets are integral to the circuitry of electric vehicles, where reliability under thermal stress is paramount. Aerospace and defense industries also harness the material’s resilience for mission-critical systems, such as satellite communication devices. Even in renewable energy, FR4 sheets play a pivotal role in the circuitry of solar inverters and wind turbine controls, showcasing their adaptability across diverse sectors.

Why Manufacturers Choose FR4 Over Alternatives?

With a plethora of insulating materials available, what sets FR4 glass epoxy sheets apart? The answer lies in their balance of performance and cost-effectiveness. Unlike ceramics, which can be prohibitively expensive, or phenolics, which lack the same level of thermal endurance, FR4 offers a harmonious blend of affordability and reliability. Its dielectric properties ensure minimal signal loss, a crucial factor in high-frequency applications. Additionally, the material’s dimensional stability under varying temperatures reduces the risk of warping, a common issue with lesser alternatives. Manufacturers globally recognize FR4 as a stalwart solution that delivers consistent results without breaking the bank.

The Science Behind FR4 Glass Epoxy Sheets

Thermal and Electrical Properties

Delving into the science of FR4 glass epoxy sheets reveals why they are indispensable in electronics. One of their standout attributes is their thermal resilience, with a glass transition temperature (Tg) typically ranging from 130°C to 140°C. This allows the material to endure the heat generated during soldering processes without compromising its structural integrity. Electrically, FR4 boasts a high dielectric strength, meaning it can insulate against substantial voltage without breaking down. This property is vital for preventing short circuits in densely packed PCB designs. The material’s low dissipation factor further ensures that signal integrity remains intact, even in high-frequency environments.

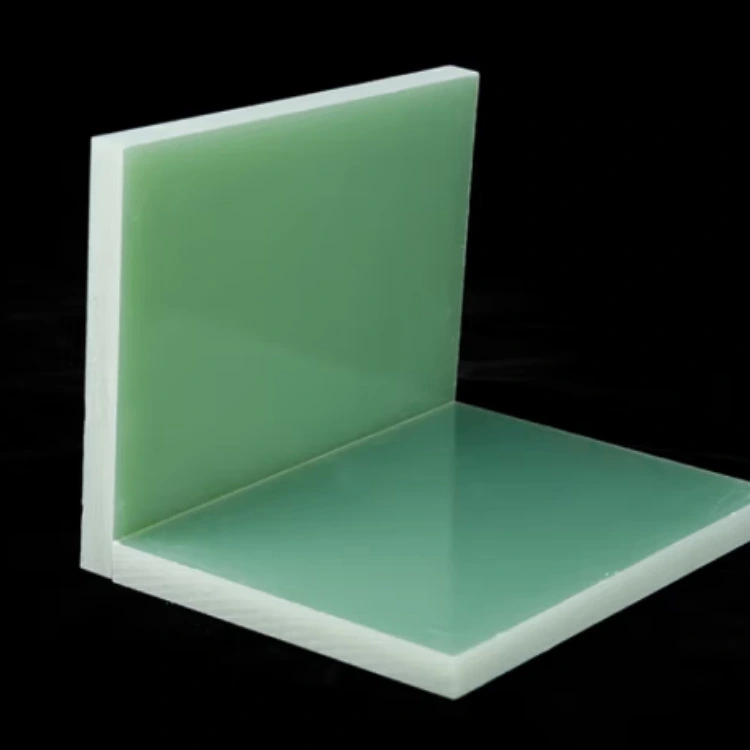

Mechanical Strength and Durability

Beyond its electrical prowess, FR4 glass epoxy sheets excel in mechanical fortitude. The woven fiberglass reinforcement imparts exceptional tensile strength, enabling the material to resist physical stress during manufacturing and operation. This durability is particularly valuable in applications where vibration or impact is a concern, such as in automotive or industrial electronics. The epoxy resin component enhances this resilience by providing resistance to moisture and chemical exposure, ensuring longevity even in harsh conditions. This combination of mechanical and environmental endurance makes FR4 a linchpin in the production of reliable, long-lasting electronic components.

Flame Retardancy and Safety Standards

Safety is a non-negotiable aspect of electronic design, and FR4 glass epoxy sheets rise to the occasion with their flame-retardant properties. The material complies with stringent industry standards, such as UL 94 V-0, which certifies its ability to self-extinguish flames within seconds of ignition. This feature is crucial in preventing catastrophic failures in devices where overheating or electrical faults could lead to fires. By incorporating brominated compounds into the epoxy resin, FR4 achieves this high level of flame resistance without sacrificing its other performance characteristics. Manufacturers can thus trust FR4 to meet rigorous safety requirements across global markets.

Choosing the Right FR4 Glass Epoxy Sheet for Your Needs

Understanding Thickness and Tolerance

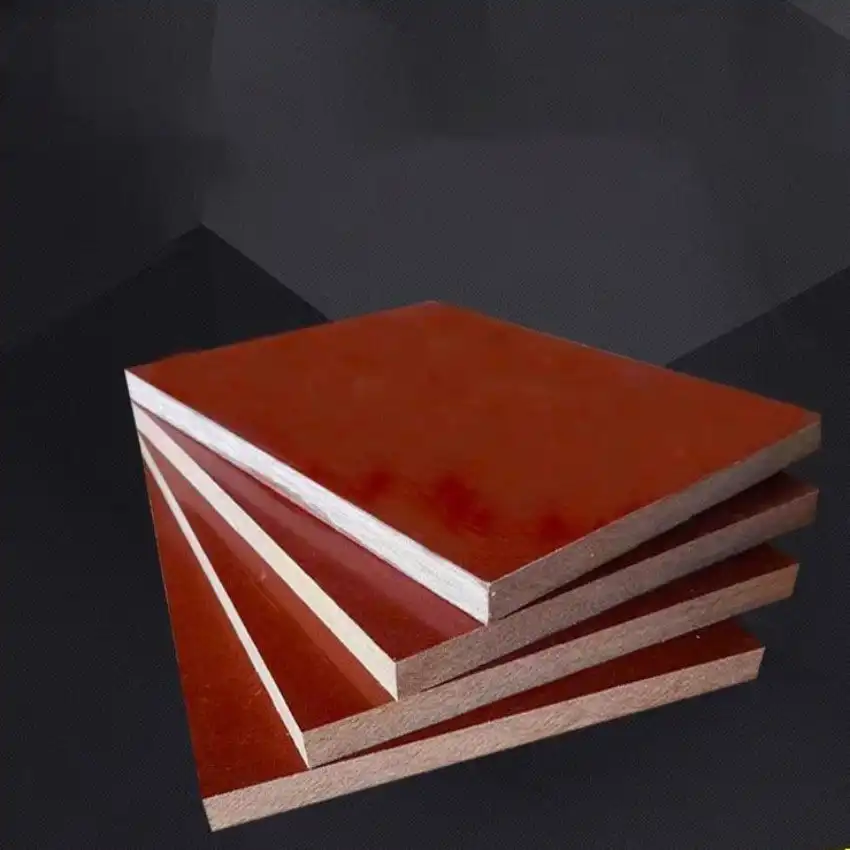

Selecting the appropriate FR4 glass epoxy sheet begins with understanding the nuances of thickness and tolerance. These sheets are available in a range of thicknesses, typically from 0.2 mm to over 50 mm, depending on the application. Thinner sheets are ideal for compact, lightweight devices, while thicker variants provide enhanced mechanical support in heavy-duty systems. Tolerance, or the allowable deviation in thickness, is another critical factor. High-precision applications, such as in medical devices, demand tight tolerances to ensure consistent performance. Manufacturers must evaluate these parameters to align the material’s specifications with their project’s unique demands.

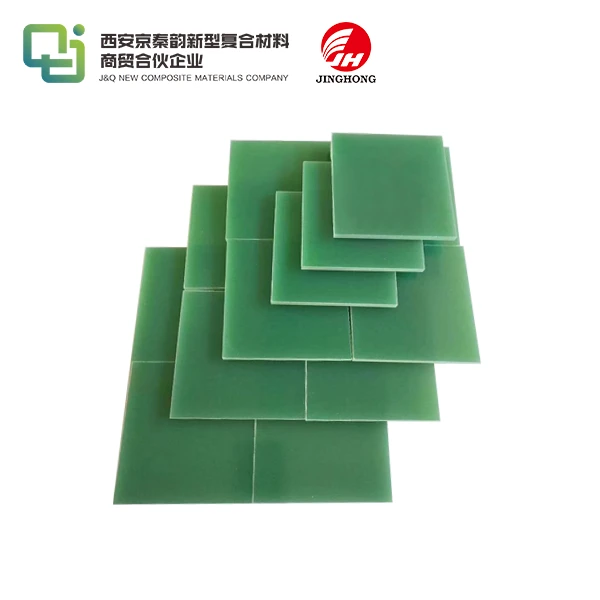

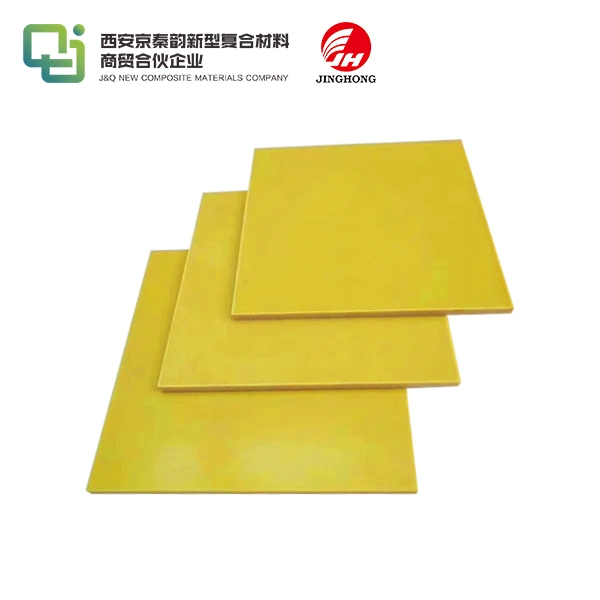

Customization Options for Specific Applications

One of the unsung advantages of FR4 glass epoxy sheets is their potential for customization. Suppliers often offer options such as copper cladding, which is essential for PCB fabrication, or surface finishes like HASL (Hot Air Solder Leveling) to enhance solderability. For applications requiring even greater thermal resistance, high-Tg FR4 variants are available, with glass transition temperatures exceeding 170°C. Color variations, such as green, blue, or black, can also be specified for aesthetic or branding purposes. This flexibility allows manufacturers to tailor FR4 sheets to their exact needs, ensuring optimal performance in specialized applications.

Partnering with a Trusted Supplier

The quality of FR4 glass epoxy sheets can vary significantly depending on the supplier, making it imperative to partner with a reputable provider. A supplier with decades of experience, such as one with over 20 years in producing insulating sheets and a decade in foreign trade, brings invaluable expertise to the table. Such a partner can offer not only high-quality materials but also comprehensive support, from material selection to after-sales service. Collaborating with a supplier that has established relationships with global trading companies ensures access to consistent, reliable products, no matter where your operations are based.

Conclusion

FR4 glass epoxy sheets stand as a testament to the ingenuity of modern materials science, underpinning the functionality of countless electronic devices worldwide. Their unique blend of thermal resilience, electrical insulation, and mechanical strength makes them an unrivaled choice for manufacturers across industries. By understanding their properties, applications, and customization options, businesses can harness the full potential of this versatile material. As electronics continue to evolve, FR4 remains a steadfast ally in driving innovation and reliability.

Contact Us

Ready to elevate your manufacturing with top-tier FR4 glass epoxy sheets? Contact us at info@jhd-material.com to explore how our expertise can support your next project.

References

1. "Composite Materials in Electronics: Properties and Applications" - Journal of Advanced Materials Research, Volume 45, Issue 3, 2019.

2. "Flame-Retardant Epoxy Resins: A Comprehensive Study" - Polymer Engineering and Science, Volume 52, Issue 7, 2020.

3. "Dielectric Materials for High-Frequency PCB Design" - IEEE Transactions on Components, Packaging and Manufacturing Technology, Volume 10, Issue 4, 2021.

4. "Thermal Management in Electronic Assemblies" - International Journal of Heat and Mass Transfer, Volume 63, Issue 2, 2018.

5. "Mechanical Properties of Fiberglass-Reinforced Composites" - Composites Science and Technology, Volume 78, Issue 5, 2017.

6. "Global Standards for Electronic Insulation Materials" - Materials Today: Proceedings, Volume 29, Part 1, 2020.

_1732777843529.webp)