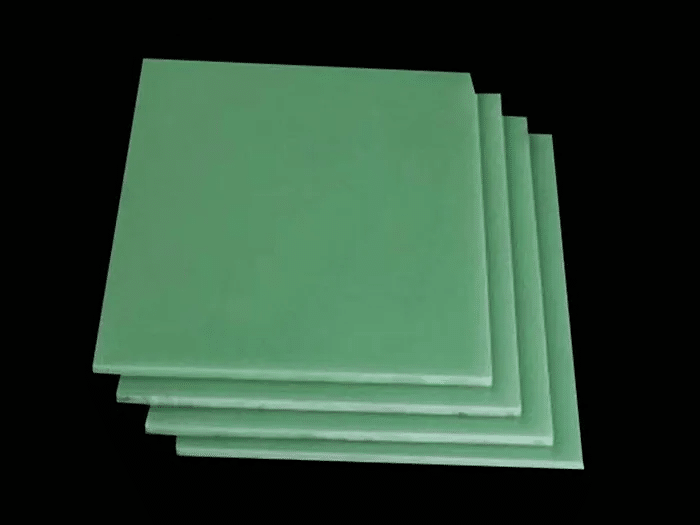

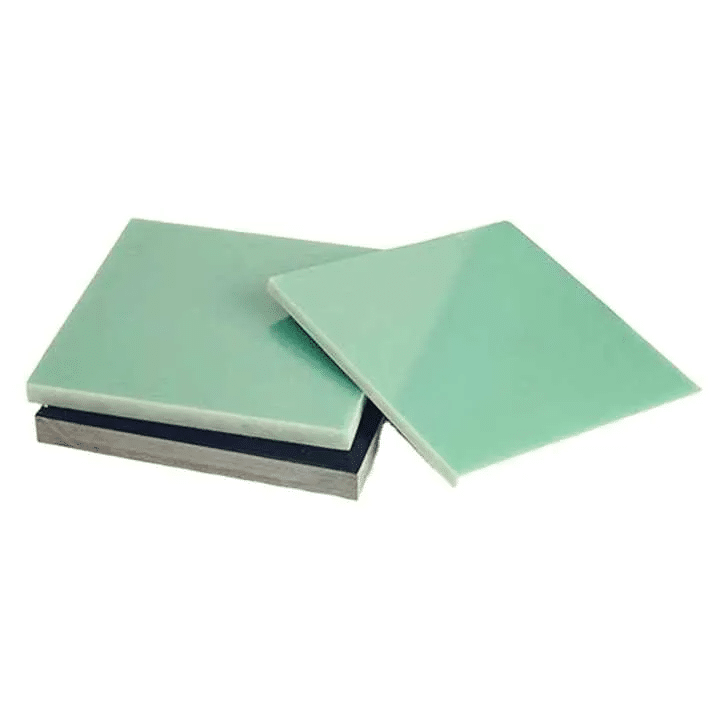

G-10 Fiberglass Plate

Basic Information:

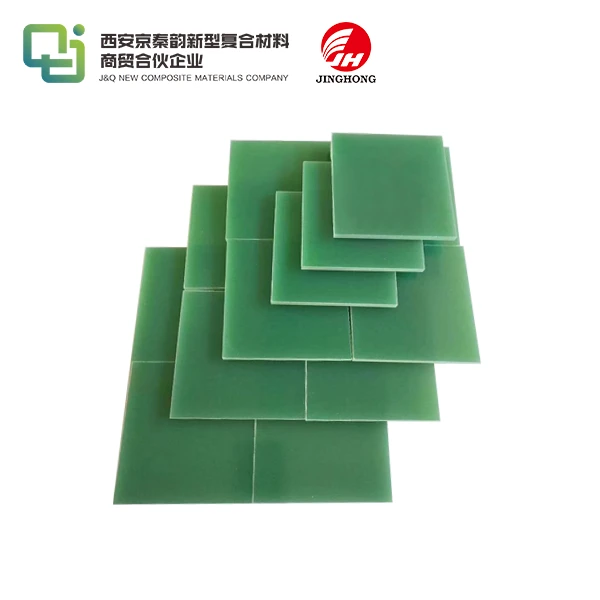

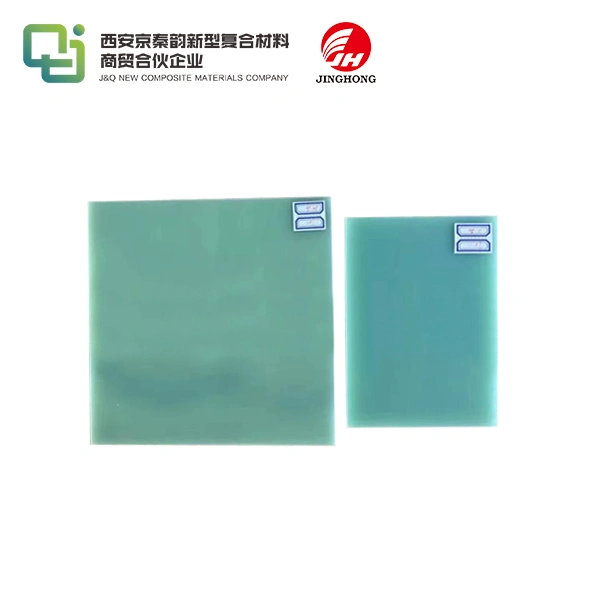

Brand: JingHong

Materials: 7628 Electronic Cloth + Epoxy Resin

Flame Retardant Grade: UL94V0

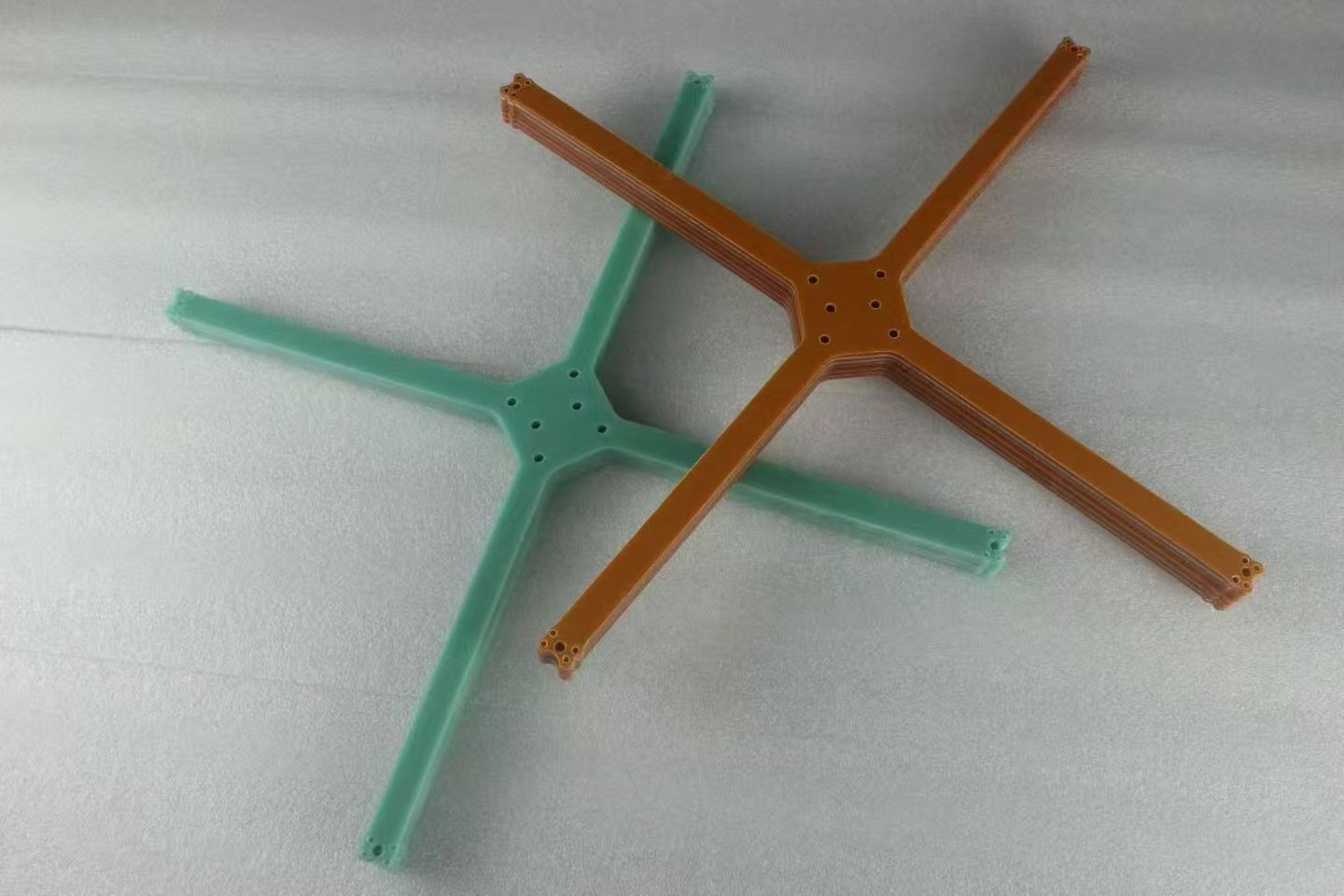

Nature Color: Light Green,Yellow,Black

Thickness: 0.3mm --- 100mm

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm, 1220mm*2440mm, 1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment: T/T

MOQ: 500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

G-10 Fiberglass Plate - Premium Industrial Grade Material

Product Description from JingHong

When you require dependable electrical separator and mechanical quality, our G-10 Fiberglass Plate conveys uncommon execution over requesting applications. This premium composite fabric combines 7628 electronic cloth with high-grade epoxy gum to make a flexible arrangement for your mechanical needs. Our G-10 plates offer predominant dimensional steadiness and fire resistance, making them the trusted choice for electrical, aviation, and fabricating businesses worldwide.

Product Availability

| Attribute | Details |

|---|---|

| Brand | JingHong |

| Materials | 7628 Electronic Cloth + Epoxy Resin |

| Colors | Light Green, Yellow, Black |

| Thickness Range | 0.3mm - 100mm |

| Standard Sizes Available | 1020mm × 1220mm, 1220mm × 2440mm, 1020mm × 2020mm |

| Custom Sizes Available | 1030mm × 2030mm, 1220mm × 2440mm, 1030mm × 1030mm, 1030mm × 2070mm |

| Minimum Order Quantity | 500KG |

| Annual Production Capacity | 30,000 Tons |

| Payment Terms | T/T |

Key Features

Our fiberglass composite plates give you with exceptional mechanical and electrical properties:

- Non-Conductive Properties: Total electrical separation for safety-critical applications

- Temperature Resistance: Performs dependably from -50°C to 130°C

- Flame Retardant: UL94V0 evaluated for upgraded fire safety

- Dimensional Solidness: Keeps up exact measurements with ±0.05 mm/m tolerance

- Chemical Resistance: Withstands destructive situations without degradation

- Non-Absorbent: Stands up to dampness and liquid penetration

Standards

Our fabricating forms follow to worldwide quality benchmarks to guarantee you get steady, dependable items. Each G-10 Fiberglass Plate meets strict industry details for electrical cover materials and composite execution requirements.

Technical Data for G10

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-1 |

GB/T 2408-2008 |

|

REMARK: 1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

Technical Features: Product Safety Control

Material Safety Properties:

- Halogen Alternatives: Both halogen and halogen-free forms available

- Fire Security: UL94V0 fire retardant classification

- Structural Keenness: Safe to shrinkage, distortion, and cracking

- Environmental Steadiness: Keeps up properties over temperature extremes

Quality Assurance:

- Rigorous testing protocols for each production batch

- Dimensional accuracy verification

- Electrical insulation performance validation

- Material composition consistency checks

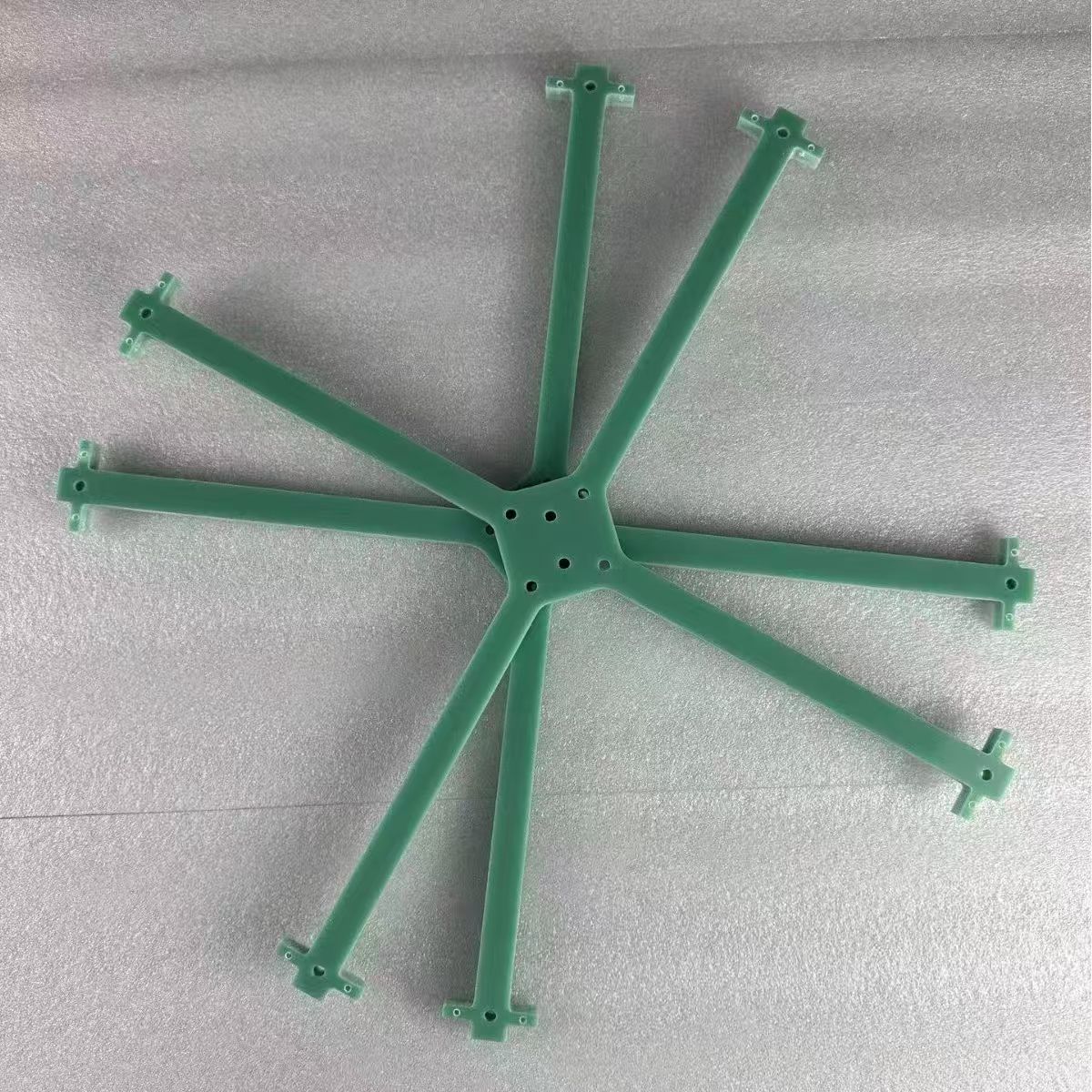

Product Applications

Your ventures can advantage from our flexible fiberglass plates over numerous industries:

Electrical Industry:

- Switchgear insulation panels

- Circuit board substrates

- Transformer components

- Electrical enclosures

Aerospace Applications:

- Interior panels

- Structural components

- Insulation systems

Manufacturing Sector:

- Jigs and fixtures

- Machine guards

- Tooling applications

- Chemical processing equipment

Marine Industry:

- Deck plates

- Structural reinforcement

- Electrical panels

OEM Service

We get it your one of a kind necessities merit customized arrangements. Our OEM administrations include:

- Custom Dimensioning: Exactness cutting to your correct specifications

- Color Coordinating: Custom colors accessible for particular applications

- Thickness Optimization: Custom fitted thickness choices for your execution needs

- Volume Generation: Adaptable fabricating to meet your generation schedules

- Technical Bolster: Master direction all through your venture development

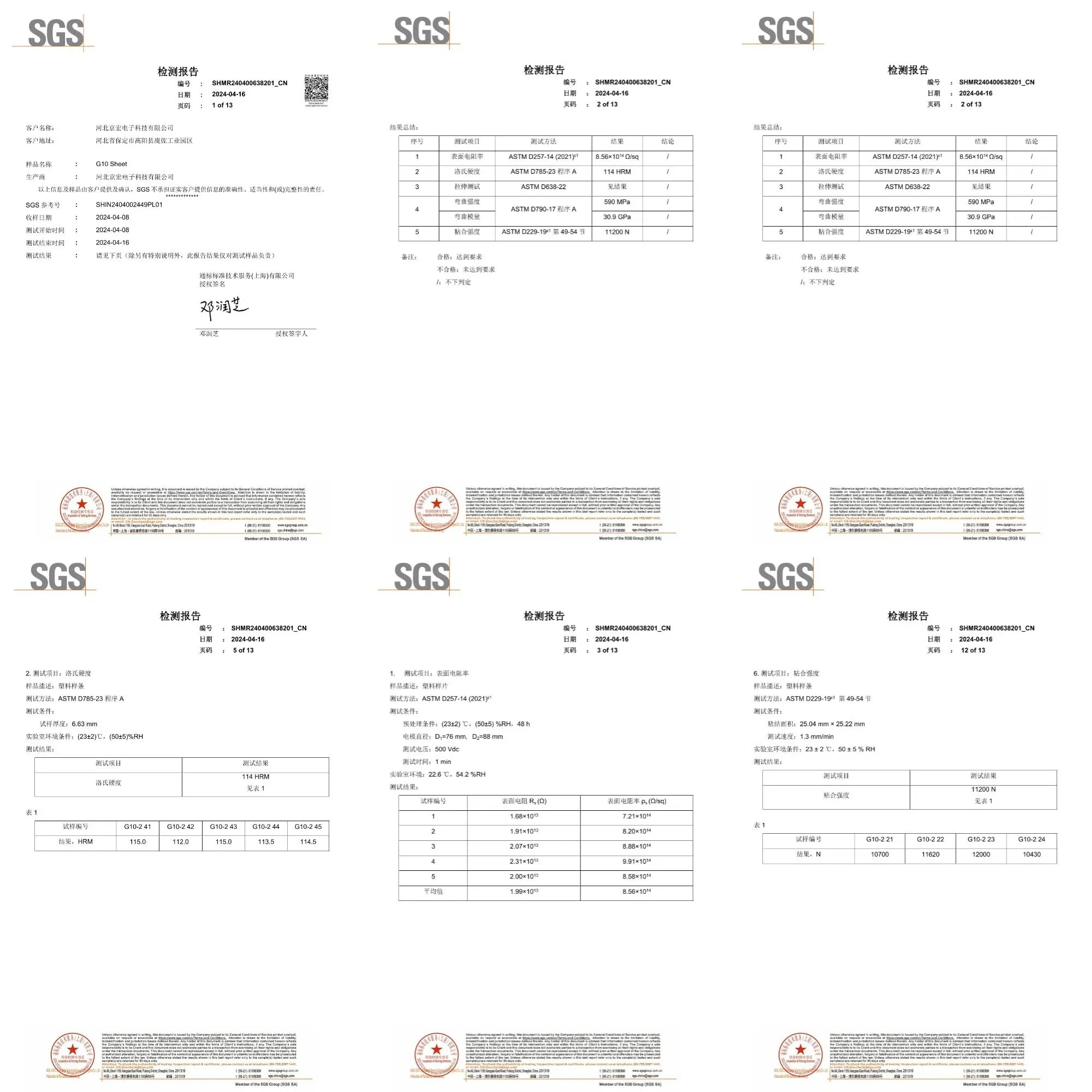

Certification

FAQ

Q: How stable are the dimensions of your fiberglass plates?

A: Our product maintains excellent dimensional stability with tolerance of ±0.05 mm/m, ensuring precision in your applications.

Q: Do your G-10 plates contain halogens?

A: We offer both halogen and halogen-free versions to meet your specific environmental and safety requirements.

Q: What temperature range can these plates withstand?

A: Your applications can operate safely within our material's temperature range of -50°C to 130°C.

Q: Are custom sizes available?

A: Yes, we provide custom cutting services to meet your exact dimensional requirements beyond our standard sizes.

Q: What packaging options do you offer?

A: We provide regular packaging with pallet protection to ensure safe transportation via ocean, land, or air freight.

Contact Us

Ready to discuss your fiberglass plate requirements? Our G-10 Fiberglass Plate technical team stands ready to help you select the perfect solution for your application needs.

Email: info@jhd-material.com

Contact us nowadays to ask tests, specialized details, or custom cites. We're committed to giving you with prevalent composite materials and uncommon benefit bolster.

Send Inquiry